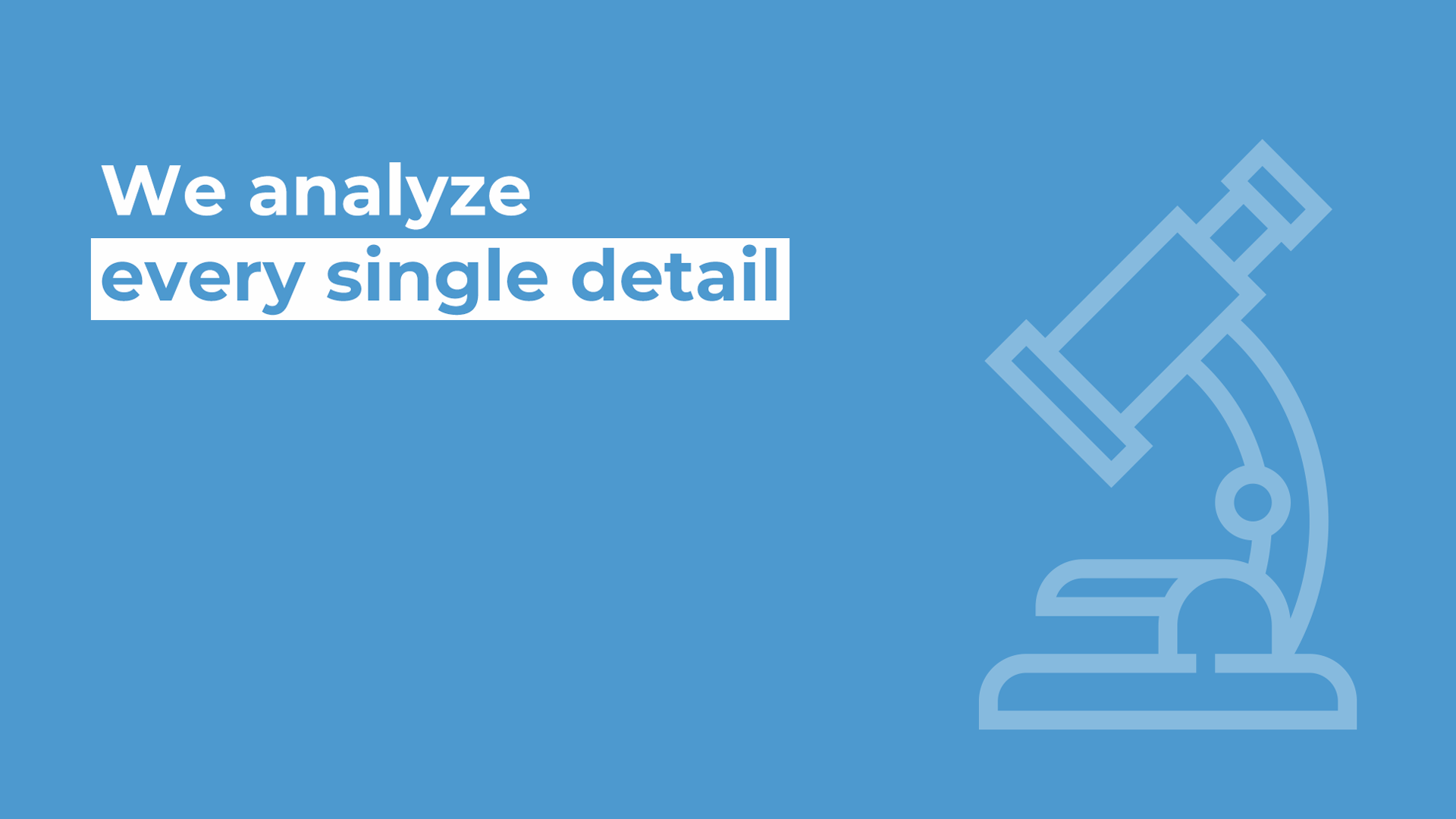

Techne's know-how and experience has always placed Quality Control as its main focus, so much so that today it is considered one of our greatest strengths. Certifications according to internationals standard and procedures of high-level quality control enable us to guarantee customers what they expect, that is competitive packaging of the highest quality.

Both certifications that meet international standards and high-level quality control procedures allow us to guarantee that our customers get what they are due: competitive packaging of the highest quality.

Reduced time

In a short time, we are able to obtain what we call process adjustment: we dynamically regulate the production process in real satisfying our customer’s quality requests.

Low costs

We avoid additional costs by making the most of our in-house laboratory.

Unique Referent

We are completely independent in implementing precise and effective quality control through a wide range of performing tools.

Our in-house laboratory enables us to control a wide range of container’s parameters.

Commonly applied controls include the following tests.

Dimensional measurement is essential in controlling and verifying the key dimensions related to the container, dimensions K, which define its intrinsic characteristics and customer’s requirements. The coordinate measuring machine Mitutoyo provides high accuracy in dimensional measurement of plastic containers, from the very first samples produced by the machine.

Samples are placed on the machine's work plane, which captures 3-axis coordinates at different pre-programmed points in the bottle, and after processing provides key measurement values. The resulting report indicates the nominal values for each K dimension, with their minimum and maximum tolerances.

Multilayer plastic containers perform key functions, such as properly preserving the product they contain and avoiding deterioration when they come into contact with certain substances. Co-extruded plastic containers or COEX are perfect for plant protection products or other aggressive chemicals, and for food packaging for their long service life, high temperature resistance and UV protection.

The analysis of the layer’s distribution in a COEX plastic container allows verifying their radial concentration at various points of the bottle and by each cavity, evaluating their possible deviation from the nominal values. The reference percentage of each layer is dictated by specific customer’s needs, the desired performance of the packaging or the type of content. The main objective of the test is to control the correct repeatability of the layer’s distribution, from the production of the first samples to the industrial phase and, therefore, to ensure the quality standards of the packaging.

Thickness analysis enables measuring a large number of points on the height and base of a plastic bottle thanks to the precision of a thickness calibrator, Magna Mike. Measurements are carried out by passing a magnetic probe over the outside of the container to be measured and placing inside a small steel ball, in this way the distance between the two components provides the thicknesses of the bottle.

The reliability and repeatability of this measurement provides useful information allowing verification of the correct distribution of the plastic, allowing control of parison’s wall thickness. Thanks to this measurement, from the first quality control specific parameters can be modified, acting directly on the control system of the parison of the machine.

In the world of plastic bottles, one of the values to be monitored is precisely weight, which often tends to be reduced to achieve significant savings in plastic material and costs. However, weight reduction can cause a change in the mechanical performance of the bottle, highlighting weaknesses areas at breakage risk.

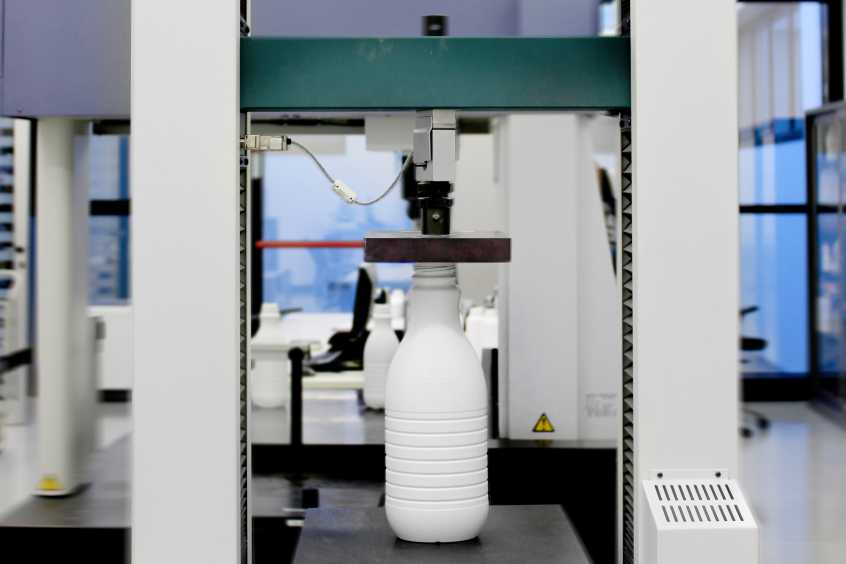

The top load test analyzes the deformation of a container subjected to a load force and verifies its resistance.

The top load test simulates typical load conditions in bottles or jerry cans during filling and capping operations or after being stacked in the warehouse. Thanks to this simulation it is possible to adjust the plastic packaging production process and predict any critical problems.

Are you planning a new project and would like to learn more about Extrusion Blow Molding technology?

Or do you have clear ideas and would like to receive a targeted advice from Techne experts?

In order to book a focused consultation and get in touch with Techne specialists, please click here below and fill in the form.